Food processing facilities: How to design a layout for success

As the second-largest manufacturing industry in the Canadian food supply chain as a percentage of GDP, it’s no surprise there are approximately 10,286 food manufacturing businesses located across the country.

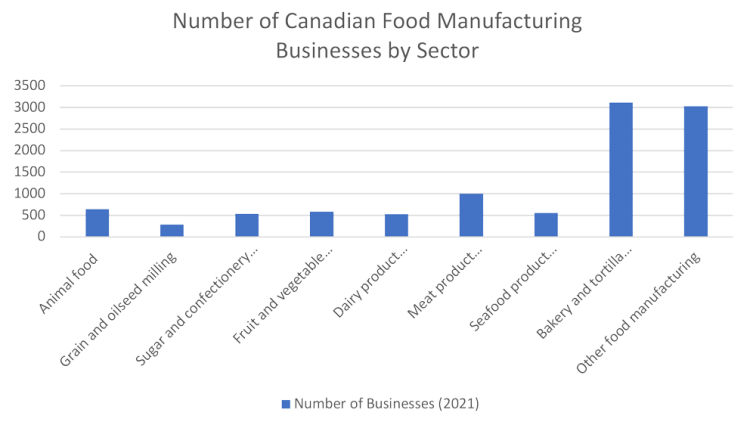

Under the food manufacturing umbrella, various sub-sectors have distinct design and layout requirements for their facilities. The table below shows the number of businesses in each sub-sector across Canada, as reported in 2021.

Figure 1: Number of Canadian food manufacturing businesses by sector

Source: Statistics Canada

All food processing businesses operate out of facilities that follow strict regulatory requirements to ensure food safety. Building designs are optimized for production efficiency, with each layout unique to the manufactured products.

For example, the layout requirements within the meat processing industry will differ whether the plant is for slaughter, raw, or ready-to-eat products. And a flour mill will look entirely different from a bakery. But all facilities have one thing in common - they transform a raw ingredient into a finished product.

Overall, the design and layout of a facility will impact the functionality and overall attractiveness on the market. Some designs and layouts can be adapted for various uses and sectors, but others are less versatile.

Appropriate planning is essential, whether looking for a facility to start production or planning for expansion by constructing a new one.

Planning for growth

Food production sales are increasing year after year. Therefore, accommodating business growth by expanding a production facility can take place in several ways, including renovation, expansion or new construction. In the site selection process for new development, a larger parcel of land is attractive for more flexibility and future expansion opportunities.

Hiring a contractor specializing in food processing plants is essential for successfully executing a new construction or renovation project. This expertise will assist with a plant design and layout, that ensures regulatory compliance and optimal production. Regulatory criteria can be at the municipal, provincial or federal level, dependent upon where the final product is going.

Several voluntary programs also impact the facility layout and run concurrently with the mandatory requirements. These voluntary programs elevate the profile of the production facility, making the final product more attractive in the marketplace. Program examples include Hazard Analysis & Critical Control Point (HACCP), British Retail Consortium (BRC) and Safe Quality Food (SQF) to name a few.

Maximizing efficiency through layout

Four main considerations to keep in mind when planning a project:

Food safety

Production efficiency

Cleanability

Versatility

With the strain on supply chains, the exterior flow of truck traffic for shipping and receiving is as critical as interior production flow. Getting raw ingredients in and the finished product out as fast as possible is a concern now more than ever.

Optimizing production flow within the plant requires adequate floor space to accommodate the processing lines, including various machinery, conveyors, and the utilities that service the equipment. The choice of materials is also crucial for the ability and ease of cleaning and sanitizing the production areas. To reduce the need for significant plant renovations, the versatility of the building design and layout to allow production equipment to be easily interchanged is important.

Automation is one way to maximize production in available space, highlighting the need for this versatility in the design. This includes floor space, building height, and utilities such as adequate power supply for automated production lines. Increased automation can be expensive, but also an attractive investment, as it can increase productivity in a climate of skilled worker shortages.

Bottom line

Food safety and production efficiency are key elements in every food processing facility, and each type of business has unique requirements. When planning for growth, a professional with expertise in food plant construction can ensure the layout of the production facility contributes to attaining food safety and production goals.

Article by: Stacey Wilks, Senior Appraiser and Alana Hinton, Senior Appraiser

Learn how bringing automation to your processing can help your business and employees thrive.